Forklift accessories At TVH, we also offer a wide range of forklift accessories, making it easy for you to keep your forklift operational at all times. Our range of forklift accessories includes lights, mirrors, camera systems and fork extensions – to name just a few. Workshop supplies, warehouse supplies and PPE. 39697 Vestil Lift Master Telescoping Fixed 15° Fork Truck Boom 32in.H Boom Telescopes to 147in. Extended Length, 4,000Lb. Capacity, Model# LM-F15-4-24 /images/product/200x200/396/39697200x200.jpg. Vestil Lift Master Telescoping Fixed 15° Fork Truck Boom — 32in.H Boom Telescopes to 147in. Extended Length, 4,000Lb. Crown is your One Source for quality forklift and pallet jack parts for more than 50 brands of material handling equipment. Tires, accessories, electric motors, warehouse and safety equipment - all available online or near you. Shop a large selection of forklift accessories like safety mirrors, heaters, handles, bumpers, and more at low everyday prices from Global Industrial. Transform your forklift into an elevated work platform. A chain secures these platforms to the forklift mast, and a backguard protects you from moving parts. Platforms also have a fork lock and two attachment points for fall restraints. Gate swings inward and outward. The walking surface has a diamond-plate texture for good slip resistance.

Modification History

Release 1. This is the first release of this unit of competency in the TLI Transport and Logistics Training Package.

Application

This unit involves the skills and knowledge required to operate a forklift in compliance with the relevant state/territory authority licence requirements and regulations, in a variety of operational contexts. It includes checking forklift condition, driving forklift to fulfil operational requirements, and monitoring and maintaining forklift performance and site conditions. Assessment of this unit will usually be undertaken within a licensing examination conducted by, or under the authority of, the relevant state/territory work health and safety (WHS)/occupational health and safety (OHS) authority. Operation of a forklift is performed under some supervision, generally within a team environment. No licensing, legislative or certification requirements apply to this unit at the time of publication. |

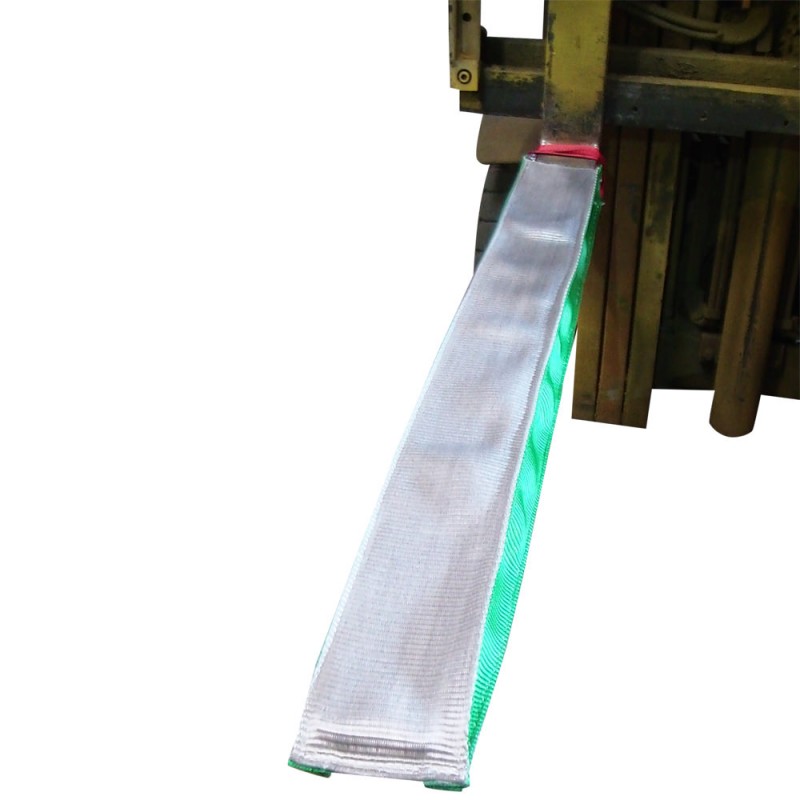

Forklift Accessories Factory

Pre-requisite Unit

Not applicable.

Competency Field

D – Load Handling

Unit Sector

Not applicable.

Elements and Performance Criteria

Flash player. Elements describe the essential outcomes. | Performance criteria describe the performance needed to demonstrate achievement of the element. | ||

1 | Check forklift condition | 1.1 | Condition of forklift is checked for compliance with WHS/OHS and workplace requirements for warning devices, manufacturer specifications and nature of load shifting task |

1.2 | Attachments are checked to ensure appropriate adjustment and operation | ||

1.3 | Mirrors and seats are adjusted for safe operation by driver | ||

1.4 | Logbooks are checked and appropriate workplace documentation is completed in accordance with workplace requirements | ||

2 | Drive forklift | 2.1 | Forklift is started, steered, manoeuvred, positioned and stopped in accordance with regulations and manufacturer instructions |

2.2 | Engine power is managed to ensure efficiency and performance and to minimise engine and gear damage | ||

2.3 | Operational hazards are identified and/or anticipated and avoided or controlled through defensive driving and appropriate hazard control techniques | ||

2.4 | Forklift is driven in reverse, maintaining visibility and achieving accurate positioning | ||

2.5 | Forklift is parked, shut down and secured in accordance with manufacturer specifications, regulations and workplace procedures | ||

3 | Operate forklift to handle loads | 3.1 Download this browser extension to stop Facebook (and Instagram) from tracking you around the web. Sync your devices. Firefox is available on all your devices; take your tabs, history and bookmarks with you. All you need is a Firefox account. Foxfire download. | Lifting task to be undertaken is appropriately planned, and correct lifting truck and attachments are selected |

3.2 | Load is lifted, carried, lowered and set down in accordance with WHS/OHS legislation, manufacturer specifications and company procedures | ||

4 | Monitor site conditions | 4.1 | Hazards and traffic flow are identified when selecting the most efficient route and appropriate adjustments are made |

4.2 | Site conditions are assessed to enable safe operations and to ensure no injury to people or damage to property, equipment, loads or facilities occurs | ||

5 | Monitor and maintain forklift performance | 5.1 | Performance and efficiency of vehicle operation is monitored during use |

5.2 | Defective/irregular performance and malfunctions are reported to relevant personnel | ||

5.3 | Forklift records are maintained/updated in accordance with workplace procedures and legislative requirements |

Foundation Skills

Foundation skills essential to performance are explicit in the performance criteria of this unit of competency.

Range of Conditions

Competency Field

D – Load Handling

Unit Sector

Not applicable.

Elements and Performance Criteria

Flash player. Elements describe the essential outcomes. | Performance criteria describe the performance needed to demonstrate achievement of the element. | ||

1 | Check forklift condition | 1.1 | Condition of forklift is checked for compliance with WHS/OHS and workplace requirements for warning devices, manufacturer specifications and nature of load shifting task |

1.2 | Attachments are checked to ensure appropriate adjustment and operation | ||

1.3 | Mirrors and seats are adjusted for safe operation by driver | ||

1.4 | Logbooks are checked and appropriate workplace documentation is completed in accordance with workplace requirements | ||

2 | Drive forklift | 2.1 | Forklift is started, steered, manoeuvred, positioned and stopped in accordance with regulations and manufacturer instructions |

2.2 | Engine power is managed to ensure efficiency and performance and to minimise engine and gear damage | ||

2.3 | Operational hazards are identified and/or anticipated and avoided or controlled through defensive driving and appropriate hazard control techniques | ||

2.4 | Forklift is driven in reverse, maintaining visibility and achieving accurate positioning | ||

2.5 | Forklift is parked, shut down and secured in accordance with manufacturer specifications, regulations and workplace procedures | ||

3 | Operate forklift to handle loads | 3.1 Download this browser extension to stop Facebook (and Instagram) from tracking you around the web. Sync your devices. Firefox is available on all your devices; take your tabs, history and bookmarks with you. All you need is a Firefox account. Foxfire download. | Lifting task to be undertaken is appropriately planned, and correct lifting truck and attachments are selected |

3.2 | Load is lifted, carried, lowered and set down in accordance with WHS/OHS legislation, manufacturer specifications and company procedures | ||

4 | Monitor site conditions | 4.1 | Hazards and traffic flow are identified when selecting the most efficient route and appropriate adjustments are made |

4.2 | Site conditions are assessed to enable safe operations and to ensure no injury to people or damage to property, equipment, loads or facilities occurs | ||

5 | Monitor and maintain forklift performance | 5.1 | Performance and efficiency of vehicle operation is monitored during use |

5.2 | Defective/irregular performance and malfunctions are reported to relevant personnel | ||

5.3 | Forklift records are maintained/updated in accordance with workplace procedures and legislative requirements |

Foundation Skills

Foundation skills essential to performance are explicit in the performance criteria of this unit of competency.

Range of Conditions

Range is restricted to essential operating conditions and any other variables essential to the work environment.

Non-essential conditions can be found in the Companion Volume Implementation Guide.

Unit Mapping Information

This unit replaces and is equivalent to TLID2010A Operate a forklift.

Forklift Accessories For Sale

Links

Companion Volume implementation guides are found in VETNet - https://vetnet.gov.au/Pages/TrainingDocs.aspx?q=df441c6e-213d-43e3-874c-0b3f7036d851